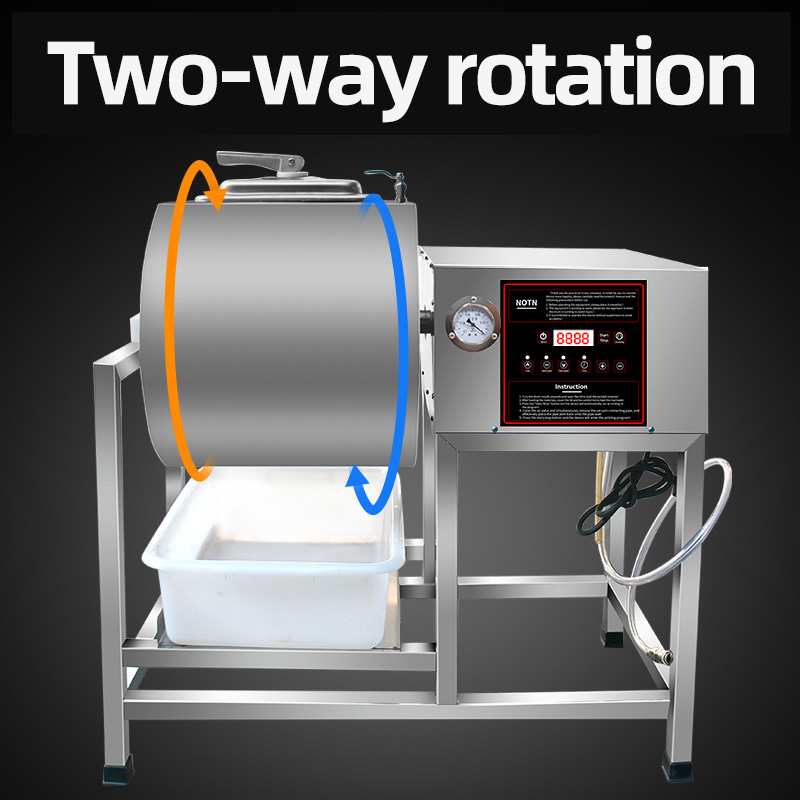

Fully Automatic Meat Marinating Machine|Vacuum Meat Marinating Machine|Marinating Machine

Product dimensions : 850*440*820mm

Drum dimensions : 380*380*360mm

Weight : 23.70kg

Voltage : 220v

Motor Power : 90w

Vacuum pump power : 220w

Email: food_machinery@hotmail.com

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address