What is a Vacuum pickling machine?

Vacuum pickling machine is a device that uses vacuum technology to pickle food. It usually includes a vacuum marinating chamber and a vacuum pump system.

During the vacuum marinating process, the ingredients and marinating liquid are placed in the vacuum marinating chamber. Subsequently, the vacuum pump will extract the air in the room to create a low-pressure environment in the marinating room, thereby achieving a vacuum state. In the vacuum state, the cell structure of the food will expand, which will help the seasoning liquid penetrate into the food, speed up the pickling speed, and make the pickling effect more uniform.

Vacuum marinating machines usually have the function of adjusting vacuum degree, marinating time and temperature, which can be adjusted according to different ingredients and marinating needs. Because vacuum pickling can improve the permeability of seasonings, make the pickling effect better, and shorten the pickling time, it is widely used in the production process of meat, seafood, soy products and other foods.

In general, the vacuum pickling machine uses vacuum technology to achieve a vacuum environment during the pickling process, which can speed up the pickling speed and improve the pickling effect. It is one of the important equipment in the food processing industry.

Pickling machine features

-

Uniform seasoning: The marinating machine can ensure that the ingredients fully contact and absorb the seasonings, achieving uniform seasoning, thereby ensuring the consistency of the texture and taste of the ingredients.

-

Improve pickling efficiency: The pickling machine uses mechanical stirring or circulating pumps to quickly and evenly apply seasonings on the surface of ingredients or soak them in them, improving pickling efficiency.

-

Save labor costs: The automated pickling machine can reduce manual operations, reduce labor costs, and improve production efficiency.

-

Maintain the quality of ingredients: The marinating machine can control the temperature and time during the marinating process to avoid over-processing, thereby maintaining the quality, taste and nutrition of the ingredients.

-

Versatility: Some advanced marinating machines may have multiple marinating methods and parameter adjustment functions, which can be adjusted and set according to different ingredients and marinating needs.

-

Hygiene and safety: Marinating machines are usually made of stainless steel or food-grade materials, which are easy to clean and disinfect, and can ensure the hygiene and safety of food processing.

-

Energy saving and environmental protection: Some advanced pickling machines may use energy-saving technology to reduce energy consumption and reduce the impact on the environment.

Pickling effect of pickling machine

The pickling effect of the pickling machine refers to whether the ingredients can fully absorb the seasonings and achieve a uniform pickling state during the pickling process, thereby maintaining the taste, quality and taste of the ingredients.

-

Seasoning liquid concentration and formula: The concentration and formula of the pickling liquid are crucial to the pickling effect. The appropriate concentration and formula of seasoning liquid can ensure that the ingredients fully absorb the seasoning and achieve a uniform marinating effect.

-

Marinating time and temperature: Marinating machines usually have the function of adjusting marinating time and temperature. Proper marinating time and temperature can ensure that the ingredients fully absorb the seasonings during the marinating process, while avoiding over-processing and maintaining the quality and taste of the ingredients.

-

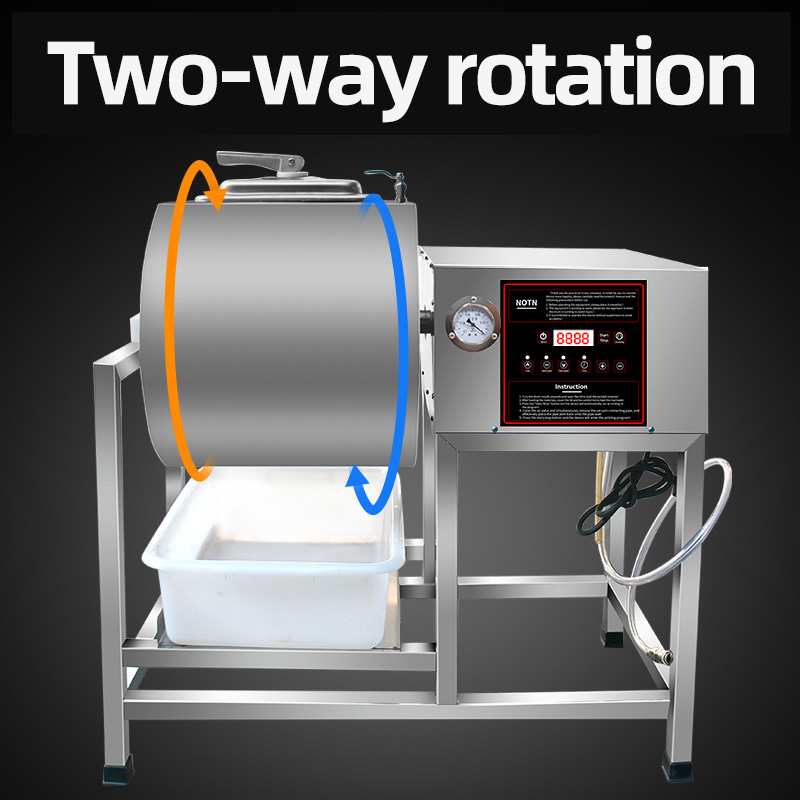

Pickling method: The pickling method of the pickling machine includes soaking, spraying, stirring, etc. Different pickling methods may affect the pickling effect. You need to choose the appropriate pickling method according to the characteristics of the ingredients and pickling needs.

-

Ingredient processing: The way in which ingredients are processed will also affect the pickling effect. For example, factors such as the cutting size and surface treatment of the ingredients will affect the absorption of seasonings by the ingredients.

-

Mechanical design and operating technology: The mechanical design and operating technology of the pickling machine will also affect the pickling effect. High-quality marinating machines usually have a uniform stirring or spraying system to ensure that the seasoning liquid is evenly applied to the surface of the ingredients or soaked in them to improve the marinating effect.

How long does it take to marinate?

The time required for marinating depends on many factors, including the type of ingredients being marinated, the size and thickness of the ingredients, the formula and concentration of the marinating liquid, and the temperature of the marinating.

- Types of ingredients: Different types of ingredients may require different marinating times. For example, marinating meats usually requires a longer time to ensure that the seasoning liquid fully penetrates into the ingredients, while marinating vegetables may require a shorter time.

- Ingredient size and thickness: The size and thickness of the ingredients will also affect marinating time. Larger or thicker ingredients may need longer to marinate to ensure that the seasoning liquid penetrates evenly into the ingredients.

- The formula and concentration of pickling liquid: The formula and concentration of pickling liquid will affect the speed and effect of pickling. Generally speaking, a pickling liquid with a higher concentration will shorten the pickling time, but a too high concentration may affect the taste and texture of the ingredients.

- Pickling temperature: Pickling temperature is also an important factor affecting pickling time. Higher temperatures usually speed up the marinating process, but too high a temperature may affect the quality of the ingredients.

Technical parameters of vacuum pickling machine

|

Models

|

Product dimensions

|

Drum dimensions

|

Weight

|

Voltage

|

Motor Power

|

Vacuum pump power

|

|

Type 45

|

850*440*800mm

|

380*350*300mm

|

23.05kg

|

220v

|

90w

|

220w

|

|

Type 55

|

850*440*810mm

|

380*360*315mm

|

23.25kg

|

|

Type 65

|

850*440*820mm

|

380*380*360mm

|

23.70kg

|

|

Type 80

|

850*440*930mm

|

380*455*425mm

|

25.10kg

|

120w

|

|

Type 100

|

960*500*1010mm

|

478*458*426mm

|

34.30kg

|

|

Type 120

|

960*500*1020mm

|

478*790*460mm

|

35.45kg

|

Pickling machine features

Energy saving and environmental protection:

-

Efficient energy utilization: Modern marinating machines usually adopt advanced energy-saving technologies, such as energy recovery systems or intelligent temperature control systems, to maximize energy utilization efficiency.

-

Energy-saving design: The design of pickling machines usually takes into account energy-saving factors, such as optimized heating and refrigeration systems to reduce energy consumption.

-

Environmentally friendly materials: Marinating machines are usually made of environmentally friendly materials, such as stainless steel or food-grade materials, ensuring that the manufacturing and use process of the machine is environmentally friendly.

Ease of operation:

-

Intelligent control: Modern marinating machines are usually equipped with intelligent control systems with simple and intuitive operation interfaces that can easily set parameters and monitor the marinating process through touch screens or buttons.

-

Automation function: Marinating machines usually have automatic functions, such as automatic spraying, automatic stirring, etc., to reduce manual intervention and improve operation convenience.

-

Easy to clean and maintain: Marinating machines are designed with ease of cleaning and maintenance in mind, often using removable parts or anti-stick coatings to facilitate cleaning and maintenance and reduce downtime.

How to ensure safety of use?

-

Follow the operating manual: Strictly follow the operating manual of the vacuum marinating machine to learn more about the use of the machine, safety precautions and emergency procedures.

-

Regular inspection and maintenance: Regular inspection and maintenance of the vacuum pickling machine, including checking whether the external and internal parts of the machine are intact, lubricating bearings, cleaning filters, etc., to ensure the normal operation and safety of the machine

-

Use appropriate accessories: Use accessories and consumables that meet specifications and standards, and avoid using unsuitable or damaged accessories to ensure machine safety and performance.

-

Pay attention to the vacuum pump system: Check and maintain the vacuum pump system regularly to ensure it is operating properly and to avoid potential failure or damage. Operators should regularly check the status of the vacuum pump and note abnormalities.

-

Emergency stop device: Make sure the vacuum marinating machine is equipped with an emergency stop button or switch to stop the machine immediately in the event of an emergency and take necessary emergency measures.

-

Maintain a well-maintained working environment: Keep the working area of the vacuum marinating machine clean and tidy, ensure that the working environment meets safety standards, and avoid accidents caused by debris or impurities.

About us

Foshan Guangling Food Machinery Co., Ltd.stands as a distinguished manufacturer specializing in the production of top-tier barbecue equipment. With over fifteen years of dedicated experience, our commitment to continuous innovation and the refinement of our machinery has propelled us to the forefront of the barbecue equipment industry in China. From the precision of our chicken rotisserie ovens to the perfection achieved with our fish grills, marinade machines, BBQ grills, Nut roaster machines, fried ice machines, timers, and an array of other food machinery, we provide comprehensive solutions for culinary enthusiasts. Our state-of-the-art facilities comprise independent production workshops and expansive warehouses, covering an impressive area of 10,000 square meters.Guangling takes pride in its commitment to excellence, evidenced by the application for Chinese national patents for numerous products and technologies.

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address