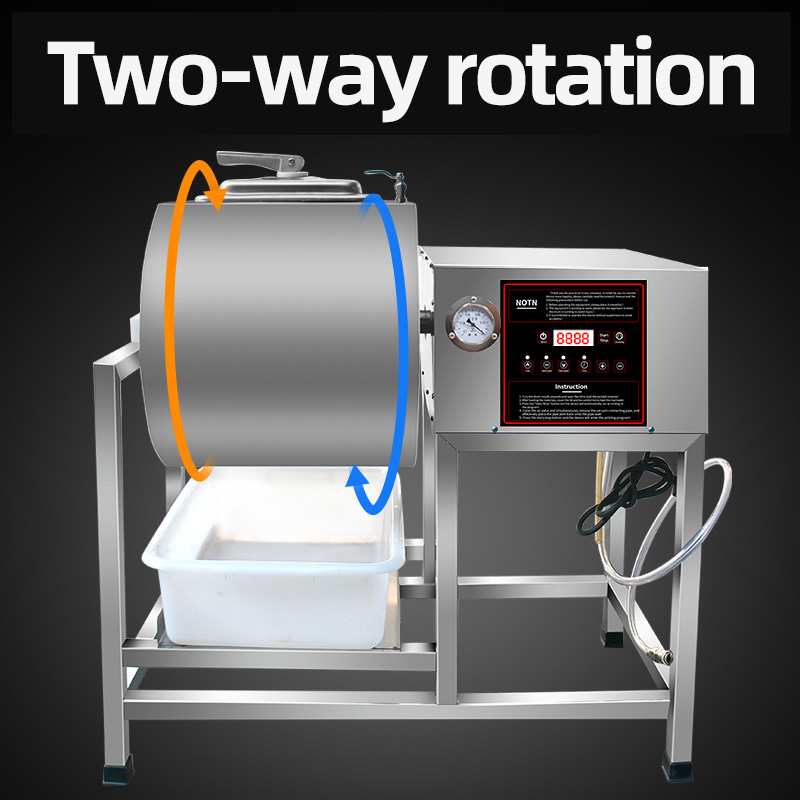

Stainless Steel Marinated Meat Salting Marinator|Chicken Salting Machiner|Marinator Machine

Product size : 960*500*1020mm

Drum size : 478*490*460mm

Voltage : 220v

Motor power : 1220w

Service : OEM & ODM

Email: food_machinery@hotmail.com

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address