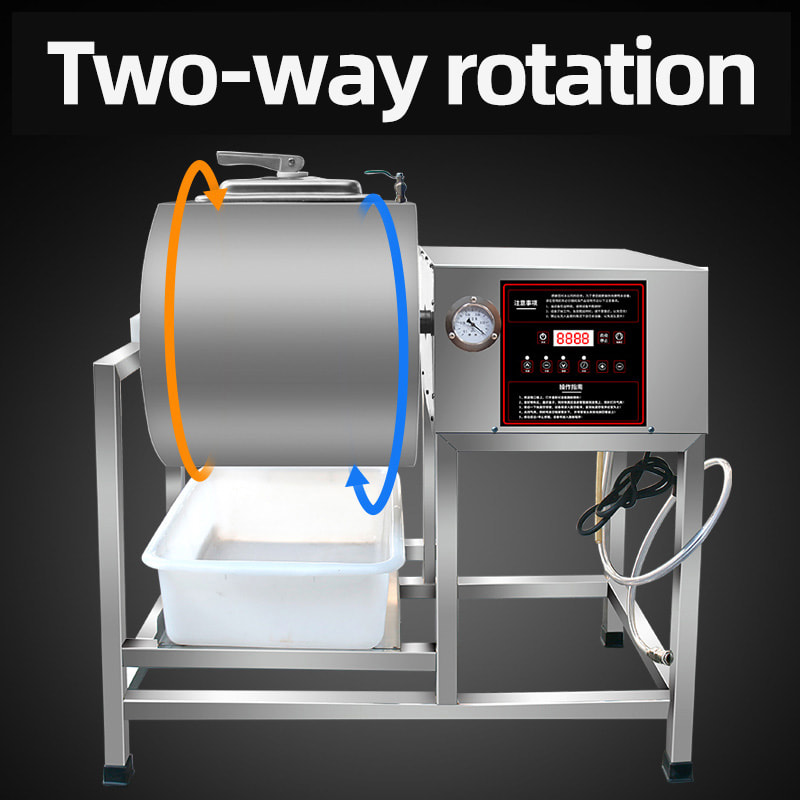

80L Large Capacity Vertical Low Noise Electric Automatic Swelling Meat Pickling Marinating Machine

Dimension(L*W*H) : 96*50*108cm

Power : 320W

Voltage : 220v/380v

MOQ : 1 Set

Service : OEM & ODM

Email: food_machinery@hotmail.com

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address